Steam n’ Spin

How might we make it easier for mothers to efficiently sanitize their breast pumps?

Steam n’ Spin is an automated breast pump part steam-sterilizer and dryer, designed for NICU-grade pathogen control and high volume use.

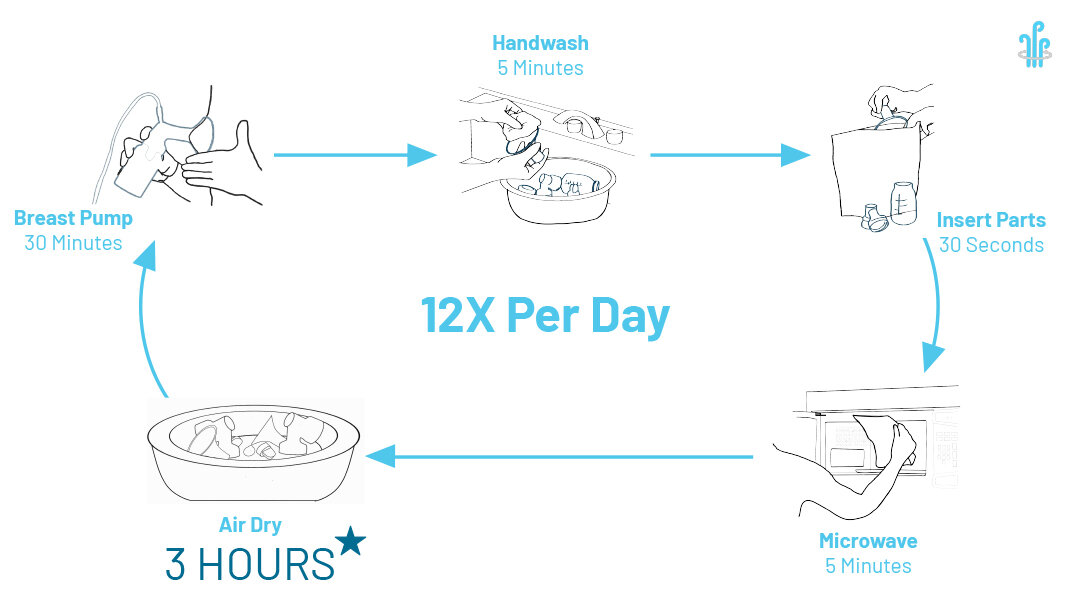

By combining steam sterilization and centrifugal drying in one unit, it dramatically reduces cleaning time and protects infants with underdeveloped immune systems from deadly infections. NICU parents breast pump 12 times per day. Currently, parents steam-sanitize their pump parts in microwaveable plastic bags and wait up to 3 hours for parts to air dry in communal NICU spaces — areas prone to spreading waterborne bacteria. Steam n’ Spin reduces drying time to 45 seconds to reduce bacterial growth.

Basket Compartments accommodate breast pump parts and counterbalance them to prevent any jostling, imbalances, and noise during the rotational drying process.

Double layered wall stays cool to the touch and allows for safe handling and placement on tabletops.

Safety sensors in the wall interface with the lid when it is securely in place, ensuring that the base only turns on when the drying unit is properly secured and the lid is closed.

TEAM MEMBERS

Aaron Herl, Prototype Lead, TJU Industrial Design

Christina Stiebris, Clinical Contact, Sidney Kimmel Medical College

Kathryn Sommer, Lead, Sidney Kimmel Medical College

Kelley Yuan, IP, Sidney Kimmel Medical College

Rachel Smith, Prototype, TJU Industrial Design

Stephanie Szymanski, Former clinical research specialist at Penn Medicine, Kanbar College of Design, Engineering and Commerce

PROject Mentors

Dr. Jessica Gaulton, MD MPH

Dr. Eddie Chang, MD MBA